Main Advantages

Wide range of products

110

The standard model range contains more than 110 units of equipment with various characteristics for any type of task

Versatile customization

30kg − 80t

Any robotic platform can be modified in accordance with the Customer’s requirements – from dimensions and load capacity to the material of execution

Easy navigation

5

R-Pro mobile robots support 5 different types of navigation, allowing them to navigate quickly and accurately in space

R-Pro Robotics offers a new line of innovative robotic products, including autonomous forklifts, mobile AGV, AMR robots and platforms, towing vehicles and much more. This equipment is designed to automate both warehouse and workshop logistics. Robots operate without human intervention, ensuring impeccable accuracy and high efficiency of production operations

Robotic forklifts

The lifting height of fork can reach 11.5 meters, which opens up additional possibilities for using the upper space and allows for rethinking the design of the production line and warehouse storage systems

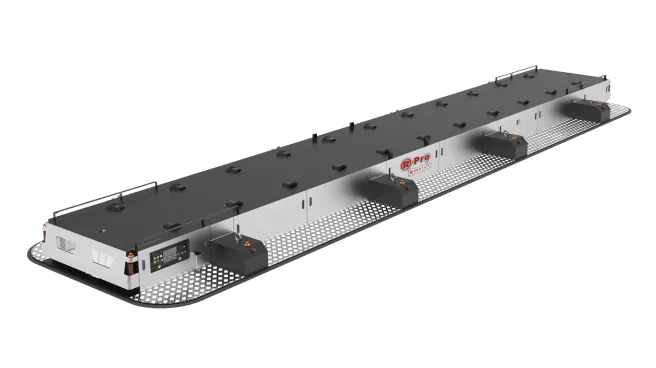

AMR and AGV robots

Mobile AMR and AGV platforms for moving racks or goods both along pre-set trajectories and flexibly orienting themselves in space, adapting to all changes and exchanging information with other robots. Optimize warehouse and workshop logistics with fast, precise and safe robotic carts

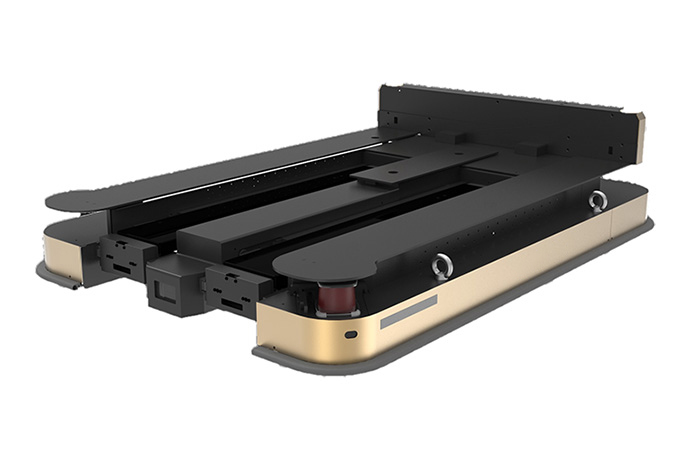

Superheavy AGVs

Automated movement of the largest loads, weighing up to 80 tons! Thanks to the installed omnidirectional wheels, rotary and linear movements can flexibly move and rotate massive objects, allowing assembly and processing

Autonomous towing vehicles

Organize an unmanned delivery route for goods between production areas or premises without additional sensors, markers or rail systems. Robotic tugboats are designed to work both indoors and outdoors

Technologies

Navigation

R-Pro mobile robots support and can be equipped with 5 main types of navigation systems, depending on the needs and requests of the Customer

Magnetic navigation

the simplest, most popular and cheapest type of movement. The movement of robotic transport occurs along magnetic tapes fixed to the floor and does not create obstacles for the movement of employees or other equipment

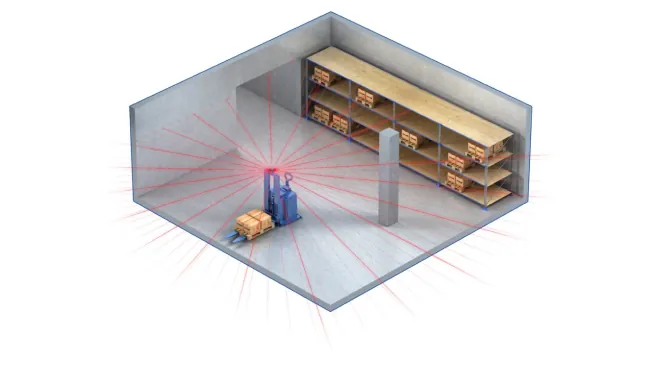

SLAM navigation

the modern method of determining the coordinates of a robot in space, in which, using built-in laser sensors, a mobile platform collects data on point clouds around itself, building a map of the room. Thanks to the network interaction of robots with each other, updated information on the boundaries of space or emerging obstacles is transmitted online, which allows to quickly lay out or change the route of movement

QR Code Navigation

a quick and inexpensive indoor method that allows AMR platforms to navigate, transmit their coordinates, and coordinate their route with other robots by scanning QR codes located on the floor

Laser navigation

determination of the coordinates of robotic transport occurs due to sensors installed in advance in the room, to which signals from moving platforms are transmitted

Inertial navigation

autonomous navigation method used to move platforms along the street, operating without additional external sensors, tags or systems. Navigation is carried out using devices installed on the mobile robot

Charging stations

To ensure efficient operation of robotic transport, engineers have provided various options for charging systems suitable for different conditions, depending on the pace of work of the Customer’s enterprise.

Autonomous R-Pro AGV and AMR platforms can be equipped with both standard wired solutions for charging batteries, requiring direct connection, and wireless options. In addition, customers have the option of an automatic battery replacement station – the entire process is fully automated, takes no more than 5 minutes and the robot is ready for full operation again!

Software

R-Pro dispatching system is the main control software responsible for AGV dispatching. Integrated with the Customer’s ERP, MES and WMS systems, it can simultaneously plan routes and manage tasks for several AGVs. R-Pro dispatching system receives instructions sent by the customer, breaks down the tasks into stages and directs the AGVs to perform their tasks within the process.

Control and programming of robotic transport is also available using the Rational Manufacturing software.

R-Pro Robotics offers services for the supply and system integration of robotic transport, AGV and AMR platforms for industrial enterprises and logistics companies in Russia and the CIS countries.